In fact, the world’s first FSC-certified maple syrup producer says it’s been the best season in his 45 years in the business. “We finished the season with 400 to 500 gallons (1,500-1,900 litres) of liquid gold,” Gary says. In an average year, his team makes 250-300 gallons (950-1,135 litres).

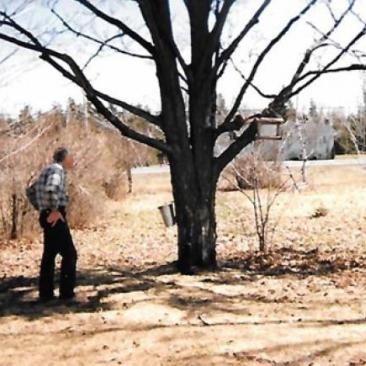

Gary is continuing the legacy of his family, who have produced liquid gold – maple syrup – on the 147-hectare Maple Ridge Farm in Cornwall in Eastern Ontario, Canada, since the original deed in 1850.

At the age of 72, he’s just spent almost three months in his sugar camp a mile into the bush for this sap season. Here, there is a well for water, a woodstove for heat, and two bedrooms for when the team has to sleep over. “We go home if the day’s sap has been boiled away into maple syrup,” he says.

It’s tough work, often in waist-deep snow in early spring. Holes are drilled into each tree to attach a vacuum system for tapping the sap, which makes its way through the tubing to the wood-burning evaporator and boilers. He’s been drawing sap from about 4,000 taps on 3,000 trees, and running a total of 40km of lines to the sugar shack, where sap is boiled down to syrup.

During sap season, Gary and his team of four to six sometimes work from 7am to 10pm. “If there is a heavy run of sap, it is not uncommon to work all night,” he says.

“As we get closer to the leaves starting to form in the trees, the sap becomes darker … There comes a time when you have to stop because the tree is close to budding and the sap becomes bitter.” That’s the end of sapping, but not the end of hard work.

First there is cleaning of tubing and equipment. Then there is processing into products like candy and maple butter, packaging, marketing and planning the next spring harvest. The farm includes activities to teach visitors about certification: what it means and why it is important.

Gary sells his syrup and products in Canada, the US, and also in markets as far as Europe and Australia. He uses the FSC logo as a sales tool. “People who know FSC … know the syrup they buy comes from a well-managed forest,” he says.

But certification involves more than sales. “It touches everything we do in the forest,” Gary explains. “Taking on the certification process has challenged me to be even more conscientious about protecting the woodlot.

“For example, we stopped hunting on the property, found all the deer yards and recorded them for follow up, identified wood that should be taken out, and found more maple trees to tap. If the FSC forest plan had not been written, we would not have done these things.”

Maple Ridge Farm is a member of the Eastern Ontario Model Forest (EOMF), which attained its FSC Forest Management group certificate through the SmartWood programme of the Rainforest Alliance in 2003. Group certification reduces the cost and administrative burden of certification for small woodlot owners.

EOMF Forest Certification Coordinator Scott Davis has watched the not-for-profit organization grow from one landowner with 20 hectares in 2000 to an 84,000-hectare programme today, involving more than 130 private owners and many community-based forests.

EOMF extended from timber to include maple syrup in its FSC certificate scope in 2007; Gary’s forest was the first to become certified in 2009. EOMF members now include five FSC-certified maple producers, which together, produce around 22,000 litres of syrup annually.

There is more to come for Gary. He plans to enlist a professional tree marker to select trees to remove from his bush for firewood. These are old trees or those that have become poor producers. “It’s part of forest management,” he says.

“My goal is to ensure my family’s forest is in place for future generations,” he adds. That … and making the world sweeter, a gallon at a time.